Liquid filter bag industrial socks filter bag

Liquid filter bag

1 It is produced by high-speed industrial sewing machines without silicone oil cooling, which will not cause the problem of silicone oil pollution.

2 . The side leakage caused by the improvement in the suture at the mouth of the bag has no high protrusion and there is no needle eye, which leads to the phenomenon of side leakage.

3 . The labels on the filter bag of the product specifications and models are all selected in a way that is easy to remove, to prevent the filter bag from contaminating the filtrate with labels and inks during use.

4 . The filtration precision ranges from 0.5 microns to 300 microns, and the materials are divided into polyester and polypropylene filter bags.

5 . Argon arc welding technology of stainless steel and galvanized steel rings. The diameter error is only less than 0.5mm, and the horizontal error is less than 0.2mm. A filter bag made of this steel ring can be installed in the equipment to improve the sealing degree and reduce the probability of side leakage.

|

Product Name

|

Liquid Filter Bags |

||

|

Material Available

|

Nylon (NMO)

|

Polyester (PE)

|

Polypropylene (PP)

|

|

Maximum Operating Temperature

|

80-100° C

|

120-130° C

|

80-100° C

|

|

Micron Rating (um)

|

25, 50, 100, 150, 200, 300, 400, 500, 600, or 25-2000um

|

0.5, 1, 3, 5, 10, 25, 50, 75, 100, 125, 150, 200, 250, 300

|

0.5, 1, 3, 5, 10, 25, 50, 75, 100,125, 150, 200, 250, 300

|

|

Size

|

1 #: 7″ x 16″ (17.78 cm x 40.64 cm)

|

||

| 2 #: 7″ x 32″ (17.78 cm x 81.28 cm) | |||

| 3 #: 4″ x 8.25″ (10.16 cm x 20.96 cm) | |||

| 4 #: 4″ x 14″ (10.16 cm x 35.56 cm) | |||

| 5 #: 6 ” x 22″ (15.24 cm x 55.88 cm) | |||

| Customized size | |||

|

Filter Bag Area(m²) /Filter Bag Volume (Liter)

|

1#: 0.19 m² / 7.9 Liter

|

||

| 2#: 0.41 m² / 17.3 Liter | |||

| 3#: 0.05 m² / 1.4 Liter | |||

| 4#: 0.09 m² / 2.5 Liter | |||

| 5#: 0.22 m² / 8.1 Liter | |||

|

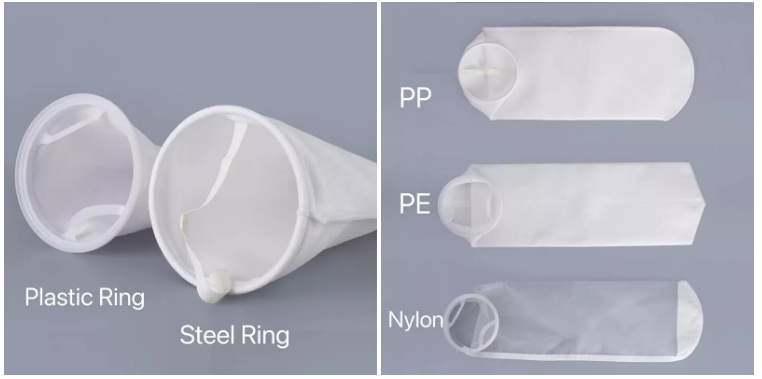

Collar Ring

|

Polypropylene ring/Polyester ring/Galvanized steel ring/

|

||

| Stainless steel ring/Rope | |||

|

Remarks

|

OEM: support

|

||

| Customized item: support. | |||

The Chemical Resistance Of Liquid Filter Bag |

|||

|

Fiber Material

|

Polyester (PE)

|

Nylon (NMO)

|

Polypropylene (PP)

|

|

Abrasion Resistance

|

Very Good

|

Excellent

|

Very Good

|

|

Weakly Acid

|

Very Good

|

General

|

Excellent

|

|

Strongly Acid

|

Good

|

Poor

|

Excellent

|

|

Weakly Alkali

|

Good

|

Excellent

|

Excellent

|

|

Strongly Alkali

|

Poor

|

Excellent

|

Excellent

|

|

Solvent

|

Good

|

Good

|

General

|