Manufacturing Companies for Folded Filter Sheets - Precoat&Support Sheets for beer and beverage – Great Wall

Manufacturing Companies for Folded Filter Sheets - Precoat&Support Sheets for beer and beverage – Great Wall Detail:

Specific Advantages

Robust sheet surface for increased sheet life and heavy duty use

Innovative sheet surface for improved cake release

Extremely durable and flexible

Perfect powder retention capacity and lowest drip-loss values

Available as folded or single sheets to fit any of the filter press sizes and type

Very tolerant of pressure transients during the filtration cycle

Flexible collocation with various filter aids which include, kieselguhr, perlites, activated carbon, polyvinylpolyprrolidone (PVPP) and other specialist treatment powders

Applications:

Great Wall support sheets work for the food and beverage industry and other applications like sugar filtration, basically anywhere where strength, product safety and durability are a key factor.

Main applications: Beer, food, fine/specialty chemistry, cosmetics.

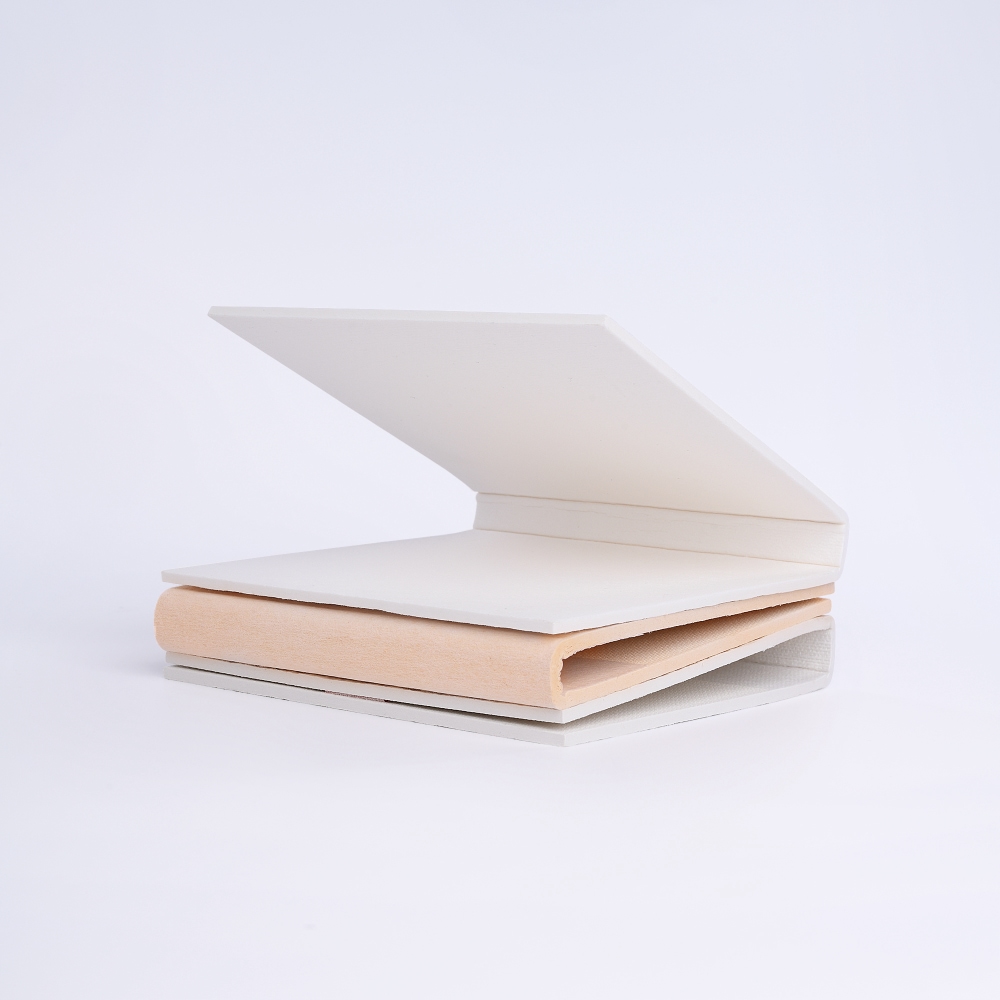

Main Constituents

Great Wall S series depth filter medium is made only of high purity cellulose materials.

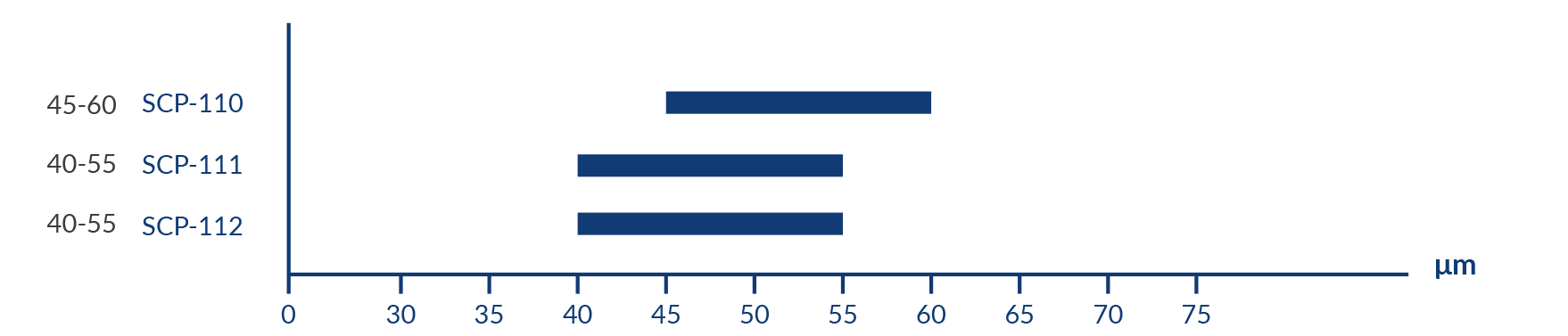

Relative Retention Rating

*These figures have been determined in accordance with in-house test methods.

*Effective removal performance of filter sheets is dependent on process conditions.

Regeneration/Backwashin

If the filtration process allows regeneration of the filter matrix, the filter sheets can be forward and back washed with softened water without bio burden to increase the total filtration capacity and thus optimizing economic efficiency.

Regeneration is carried out as follows:

Cold rinsing

in the direction of filtration

Duration approximately 5 minutes

Temperature: 59 – 68 °F (15 – 20 °C)

Hot rinsing

forward or reverse direction of filtration

Duration: approximately 10 minutes

Temperature: 140 – 176 °F (60 – 80 °C)

Rinsing flow rate should be 1½ of the filtration flow rate with counter pressure of 0.5-1 bar

Please contact Great Wall for recommendations on your specific filtration process as results may vary by product, pre-filtration and filtration conditions.

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Manufacturing Companies for Folded Filter Sheets - Precoat&Support Sheets for beer and beverage – Great Wall , The product will supply to all over the world, such as: Tunisia, Hungary, Chicago, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and solutions and good service for domestic and international customers.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.