OEM manufacturer Beverage Board Filter Frames - Plate filters and frame filters – Great Wall

OEM manufacturer Beverage Board Filter Frames - Plate filters and frame filters – Great Wall Detail:

Stainless Steel 304 or 316L Plate and Frame Filter Press for Liquid filtration Industry

The filter press is a very effective tool intended to separate solids and liquids. Stainless steel 304 filter press refers to the filter press whose plate

material are stainless steel304 or the filter press structure is cladded by SUS304. Normally, the fitter press is plate and frame design.

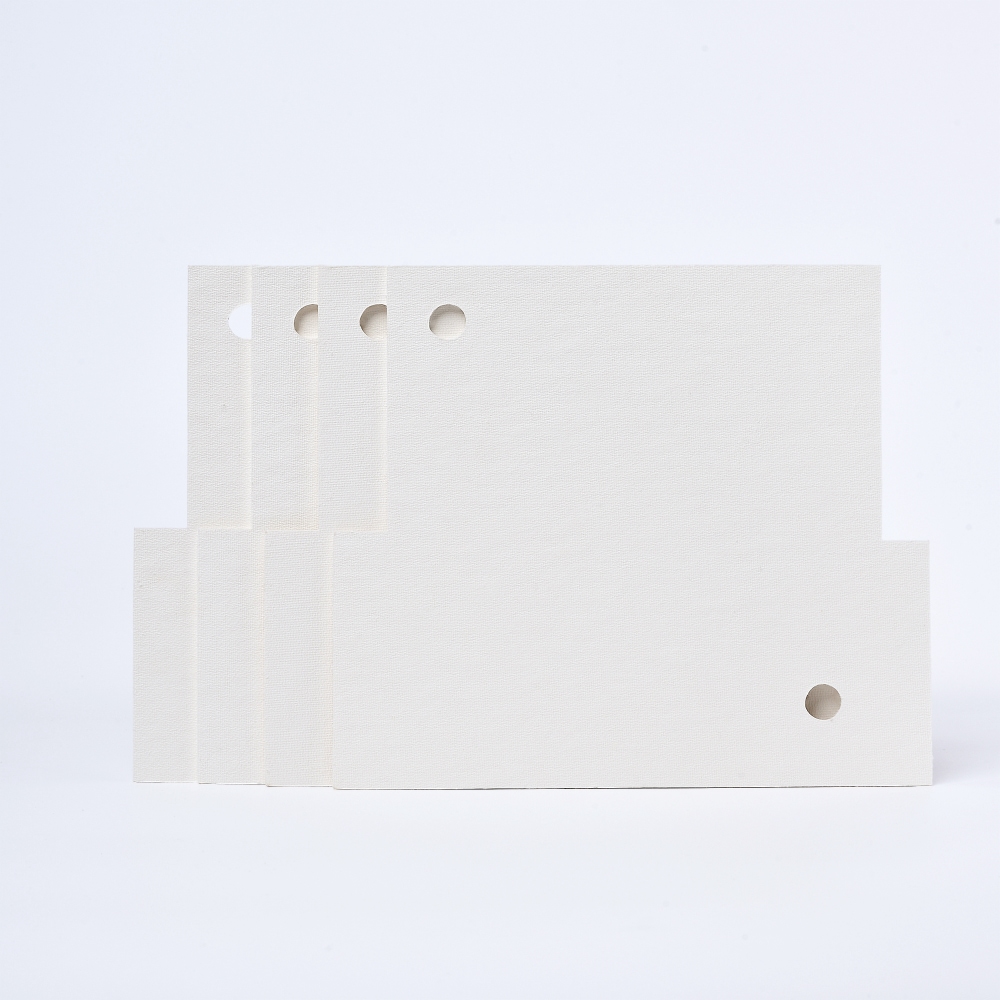

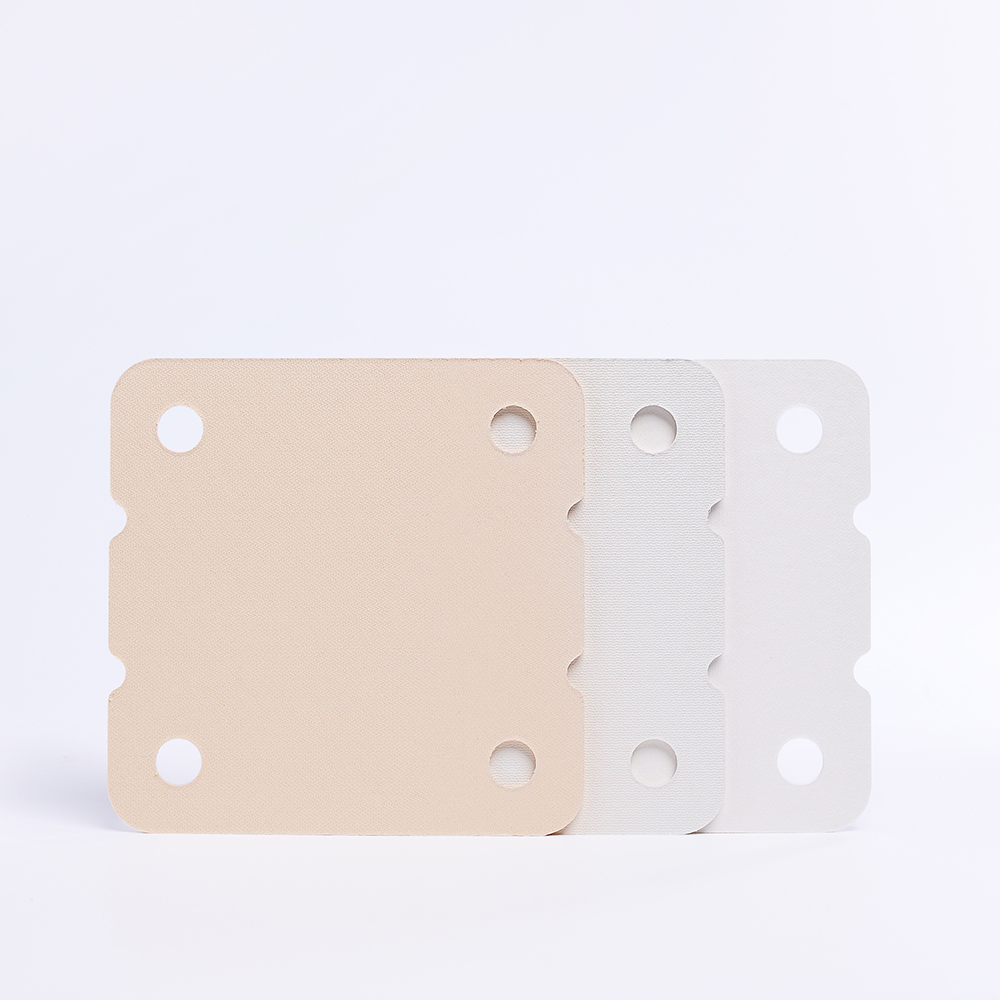

Great Wall plate and frame filters are manufactured using our superior internally ported design, offering a number of benefits over external porting. Internal ports allow for a greater choice of filter media in a broad range of material and thickness, including pads, paper and cloth. In an internally ported filter press, the filter media itself works as the gasket, eliminating concerns over gasket-product compatibility. With no need to change gaskets, you save time, money and labor. Plate and frame filters with internal ports are also inherently more sanitary since there can be no cross-contamination of O-rings from batch to batch due to product holdup.

Larger cake accumulation results in longer filtration cycles and even more importantly, the ability to achieve efficient washing of the cake to recover valuable product for further processing. Product recovery via cake washing is one of the major economic benefits of using plate and frame filter presses.

Great Wall plate and frame filter units are designed to accommodate a wide range of components. These include sludge inlet frames for cake accumulation, dividing heads for multiple-step/one-pass filtration, sanitary fittings, special piping and gauges as well as pumps and motors to meet a wide range of applications.

Product detail pictures:

Related Product Guide:

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for OEM manufacturer Beverage Board Filter Frames - Plate filters and frame filters – Great Wall , The product will supply to all over the world, such as: Tunisia, Orlando, Armenia, We always hold on the company's principle "honest, professional, effective and innovation", and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.